Bioplastics Technologies

India: A Hub for Sustainable Bioplastics

India offers a dynamic ecosystem for cost-effective bioplastics production, making it an ideal location for manufacturing innovative bioplastics.

With abundant feedstock availability, lower energy costs, and state-of-the-art research institutions, India presents unparalleled opportunities for growth and innovation in the bioplastics sector. Supported by favourable regulations and geographical advantages, India is well-positioned to become a global leader in the transition to sustainable bioplastics

Praj Industries embraces a comprehensive approach to bioplastics technology development, covering the entire production process from feedstock selection to application development. We are actively developing technologies for Polylactic acid (PLA) and Polyhydroxyalkanoates (PHA), leveraging advanced strain engineering, fermentation techniques, and efficient downstream processing, Praj ensures cost-effective bioplastics production without compromising quality or performance.

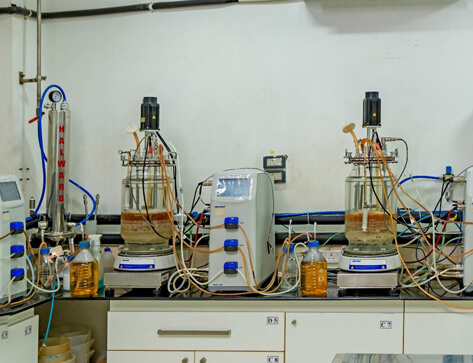

India’s first demonstration plant for showcasing indigenously developed integrated Polylactic acid technology.

The imminent launch of a demonstration plant for bioplastics production in 2024 underscores Praj's dedication to advancing sustainable solutions. The plant showcases integration capabilities and demonstrates biopolymers technologies in an end-to-end manner.

Praj’s Demonstration facility for Biopolymers is located at Jejuri, Maharashtra. Spanning approximately 3 acres, the plant features a production capacity of 100 TPA for Lactic Acid and 60 TPA for Lactide equivalent to 55 TPA of Polylactic Acid (PLA).

Process optimization integration & design and deployment - A step towards Commercialization- Demonstration Facility for Biopolymers

Major facilities at the Plant:

Feedstock processing facility

Downstream processing section

Fermentation facility

Dedicated Utilities and effluent treatment facility

Application Development

In addition to these developments, Praj has established the Parimal and Pramod Chaudhari Centre of Excellence and Innovation for Biopolymers (PPC-COEI) at the Institute of Chemical Technology, Mumbai. This Centre focuses on developing various applications for bioplastics.

End-of-Life:

Praj is actively addressing end-of-life scenarios for bioplastics, ensuring sustainable lifecycle management and contributing to a circular economy.

Polylactic acid (PLA): Pioneering Indigenous Technology in India

At Praj Industries, we stand at the forefront of revolutionizing the bioplastics industry, proudly introducing our groundbreaking Polylactic Acid (PLA) technology. With an unwavering commitment to sustainability and innovation, we are reshaping the future of plastics with solutions that redefine PLA production while significantly contributing to waste reduction.

Polylactic Acid (PLA) is a revolutionary bioplastic, derived from renewable resources such as sugary, starchy or cellulosic feedstocks. Its versatility, biodegradability, and minimal environmental impact make it a beacon of sustainability in the plastics industry through Biomanufacturing.

Why Choose PLA?

- Impact on Human Health: PLA offers a safer, more sustainable alternative

as it eventually breakdown into biogenic CO2 and water, free from harmful additives, unlike traditional fossil-fuel plastics that contribute to microplastic pollution, potentially disrupt hormones, and have been linked to certain cancers. - Eco-Friendly: PLA is crafted from plant-based materials, reducing reliance on finite resources and decreasing the carbon footprint. (ci comparison in terms of fossil plastics)

- Compostability: Unlike fossil plastics, PLA is industrially compostable, breaking down into harmless components and contributing to a cleaner environment.

- Versatile: PLA can be processed and blended with other copolymers, making it suitable for a wide range of applications, from packaging to textiles.

Praj Approach towards PLA technology

Lactic acid (LA) fermentation and purification:

- Feedstock agnostic approach – Sugary & starchy, cellulosic

- Proprietary low pH yeast and bacterial platform with high yield and productivity

- Gypsum free process

- Technology for production of Industrial, food & polymer grade LA

Lactide Synthesis:

- Novel continuous process

- High purity and yields

Process intensification:

- A 3C/Triple C approach: Best in class, Lowest in Carbon and Cost

- Join us in reshaping the future of plastics with sustainable, innovative solutions. Together, let's create a cleaner, greener tomorrow.

Discovering the Power of Polyhydroxyalkanoates (PHAs): Biobased and Biodegradable plastic

PHAs are natural polymers derived from renewable sources, which is not only versatile and eco-friendly alternative to fossil based plastics; it also fully biodegradable in soil and marine environments. Praj Industries is at the forefront of PHA technology development, unlocking the potential of diverse PHA family of biopolymers for a greener tomorrow.

Unveiling the Benefits of PHAs

PHAs boast a plethora of benefits that make them an ideal choice for sustainable packaging and products.

- Biodegradable: PHAs break down naturally in the environment, reducing plastic pollution and ecological harm.

- Renewable Sourcing: PHAs are inherently sustainable and contribute to the circular economy.

- Versatile: PHA can be processed and blended with other copolymers , making it suitable for a wide range of applications, from packaging to textiles

Praj Approach towards PHA technology

- Feedstock agnostic approach based on sugars and waste streams

- Proprietary bacterial platform for variety of PHAs

- Low CI technology

- Water based downstream processing

- IP protected with end-to-end process

Applications Across Industries

The applications of PHAs are as diverse as they are impactful.

- In the packaging industry, PHAs can be used to create films, bottles, containers, and tubs, providing a sustainable alternative to traditional plastics.

- In food and cosmetics, PHAs find their place in cutlery, containers, and films, offering both hygiene and sustainability.

- Agriculture benefits from PHA mulch films and irrigation system parts, while the pharmaceutical industry utilizes PHAs for packaging and hygienic clothing.

- High value Biomedical applications for sutures, implants, scaffolds

With PHAs, Praj Industries is at the forefront to unlock the potential of this natural and fully biodegradable biopolymer.

-

Polylactic acid: Pioneering Indigenous PLA Technology in India

-

Discovering the Power of Polyhydroxyalkanoates (PHAs): Biobased and Biodegradable plastic

Press Release

At Praj Industries, we stand at the forefront of revolutionizing the bioplastics industry, proudly introducing our groundbreaking Polylactic Acid (PLA) technology. With an unwavering commitment to sustainability and innovation, we are reshaping the future of plastics with solutions that redefine PLA production while significantly contributing to waste reduction.

Polylactic Acid (PLA) is a revolutionary bioplastic, derived from renewable resources such as sugary, starchy or cellulosic feedstocks. Its versatility, biodegradability, and minimal environmental impact make it a beacon of sustainability in the plastics industry through Biomanufacturing.

Why Choose PLA?

- Impact on Human Health: PLA offers a safer, more sustainable alternative as it eventually breakdown into biogenic CO2 and water, free from harmful additives, unlike traditional fossil-fuel plastics that contribute to microplastic pollution, potentially disrupt hormones, and have been linked to certain cancers.

- Eco-Friendly: PLA is crafted from plant-based materials, reducing reliance on finite resources and decreasing the carbon footprint. (ci comparison in terms of fossil plastics)

- Compostability: Unlike fossil plastics, PLA is industrially compostable, breaking down into harmless components and contributing to a cleaner environment.

- Versatile: PLA can be processed and blended with other copolymers, making it suitable for a wide range of applications, from packaging to textiles.

Praj Approach towards PLA technology

Lactic acid (LA) fermentation and purification:

- Feedstock agnostic approach – Sugary & starchy, cellulosic

- Proprietary low pH yeast and bacterial platform with high yield and productivity

- Gypsum free process

- Technology for production of Industrial, food & polymer grade LA

Lactide Synthesis:

- Novel continuous process

- High purity and yields

Process intensification:

- A 3C/Triple C approach: Best in class, Lowest in Carbon and Cost

- Join us in reshaping the future of plastics with sustainable, innovative solutions. Together, let's create a cleaner, greener tomorrow.

Discovering the Power of Polyhydroxyalkanoates (PHAs): Biobased and Biodegradable plastic

PHAs are natural polymers derived from renewable sources, which is not only versatile and eco-friendly alternative to fossil based plastics; it also fully biodegradable in soil and marine environments. Praj Industries is at the forefront of PHA technology development, unlocking the potential of diverse PHA family of biopolymers for a greener tomorrow.

Unveiling the Benefits of PHAs

PHAs boast a plethora of benefits that make them an ideal choice for sustainable packaging and products.

- Biodegradable: PHAs break down naturally in the environment, reducing plastic pollution and ecological harm.

- Renewable Sourcing: PHAs are inherently sustainable and contribute to the circular economy.

- Versatile: PHA can be processed and blended with other copolymers , making it suitable for a wide range of applications, from packaging to textiles

Praj Approach towards PHA technology

- Feedstock agnostic approach based on sugars and waste streams

- Proprietary bacterial platform for variety of PHAs

- Low CI technology

- Water based downstream processing

- IP protected with end-to-end process

Applications Across Industries

The applications of PHAs are as diverse as they are impactful.

- In the packaging industry, PHAs can be used to create films, bottles, containers, and tubs, providing a sustainable alternative to traditional plastics.

- In food and cosmetics, PHAs find their place in cutlery, containers, and films, offering both hygiene and sustainability.

- Agriculture benefits from PHA mulch films and irrigation system parts, while the pharmaceutical industry utilizes PHAs for packaging and hygienic clothing.

- High value Biomedical applications for sutures, implants, scaffolds

With PHAs, Praj Industries is at the forefront to unlock the potential of this natural and fully biodegradable biopolymer.