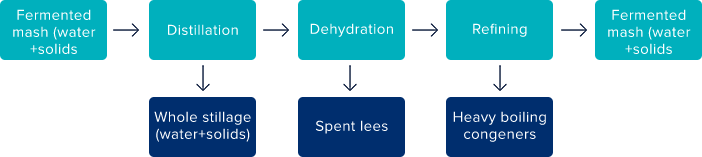

Distillation

Distillation takes advantage of the difference in boiling points of ethanol, water and other constituents formed in the fermentation section to achieve the desired purity levels, depending on the application. Praj has set benchmarks in the industry with its unique and energy efficient distillation systems.

EcoSmart Technology

Our high efficiency tower internals enable effective separation of impurities. To ensure desired quality of ethanol, factors such as impure spirit cuts, reflux ratio and congener profile are rigorously studied on simulation package for optimization. This analysis leads to constant improvement in systems for superior quality. EcoSmartdistillation technology is based on integration of distillation and dehydration sections. Distillation columns have been configured to secure the benefits of integration along with flexibility to produce different grades and concentration of ethanol as per the market demand.

Evaporative Distillation

Features

- Thermal energy similar to split distillation

- Suitable for molasses & grain based ethanol plant

- Ethanol titer in mash 8-15% v/v

Benefits

- Increase in profitability due to reduced water and energy consumption

- Modernization opportunity to expand plant capacity by 25-30%

Advantages

- Lower steam consumption as against evaporation integrated distillation

- Reduction in water footprint

- Suitable for retrofitting

- Lower CAPEX

MVR distillation

Mechanical Vapor Recompression (MVR) is a technology where vapour is compressed in a compressor or fan to a higher pressure & temperature. This compressed vapour is then used as a source of heat for distillation and evaporation instead of fresh steam. MVR system offers significant reduction in energy and water consumption.

-

Pressure vacuum distillation Ecofine-PV

Characterized by low energy consumption as a result of heat integration with evaporation and MSDH plant.

-

Multipressure distillation Ecofine-MPR

Employed for production of superfine or beverage grade/extra neutral alcohol.

-

Multipressure split distillation Ecofine-SD

Best suited where steam pressure is relatively high. Also characterized by further lower energy consumption.

Synchronous (Fed-Batch)

HiFerm Fermentation

- Proven technology with fleximode options – fed batch, continuous and Combiferm

- High fermentation efficiency with maximum yields

- Higher alcohol concentration in mash upto 15% v/v

- Allows maximum stillage recycle (upto 60% for sugar syrup) reducing substantial water usage and less stillage volume for final treatment

- Option to tap CO2 for processing to food grade quality