Using 2G Ethanol to Help Mitigate Environmental Hazards

A thick layer of smog shrouds Delhi as the capital lays enveloped in noxious mist with pollution levels now lurking under the severe plus or emergency category. According to SAFAR (System of Air Quality and Weather Forecasting And Research), the share of stubble-burning accounted for 20% to 25% of Delhi’s pollution in recent times. [1] The government also expressed its inability to control the stubble burning in Punjab and Haryana to bring pollution under control. This, in spite of the Rs 100 per quintal incentive in return for the stubble. Air pollution of this scale can aggravate heart and lung disease and also pose a serious risk to the respiratory systems of the residents. So how can 2G bioethanol production make a difference in the scenario? Let’s find out

The Role of 2nd Generation Ethanol Production Technology

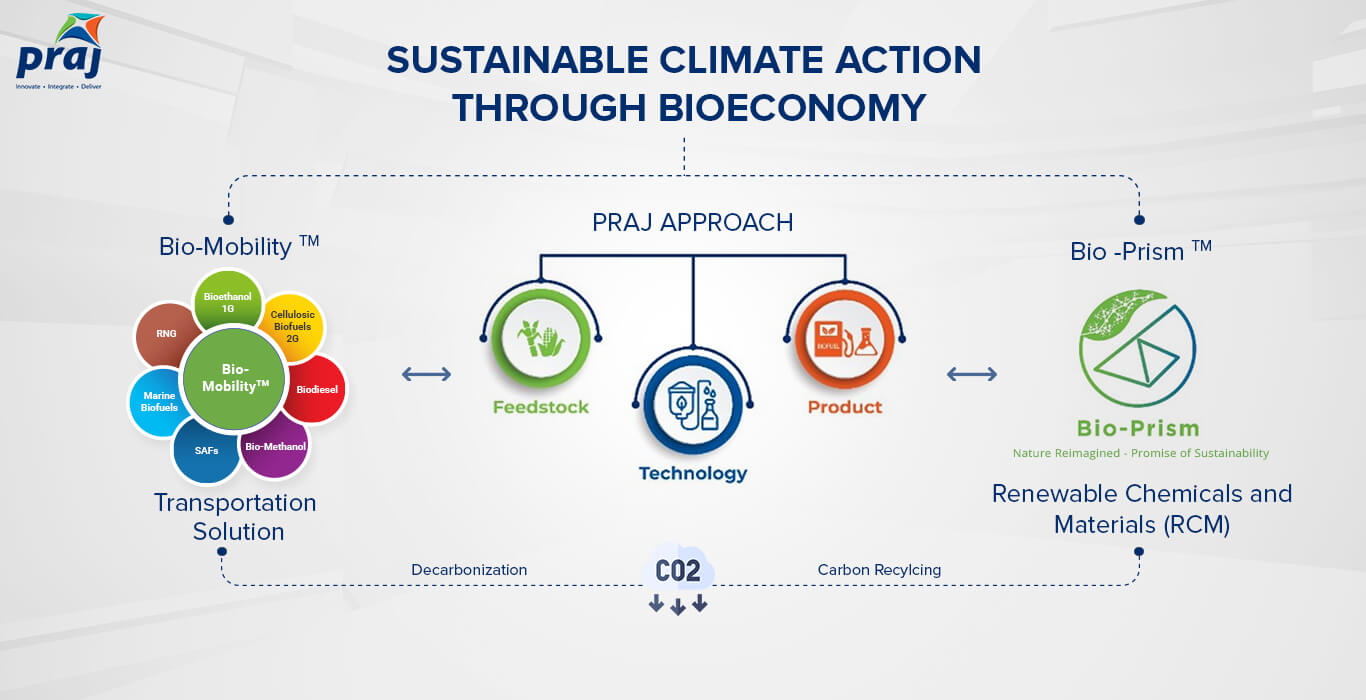

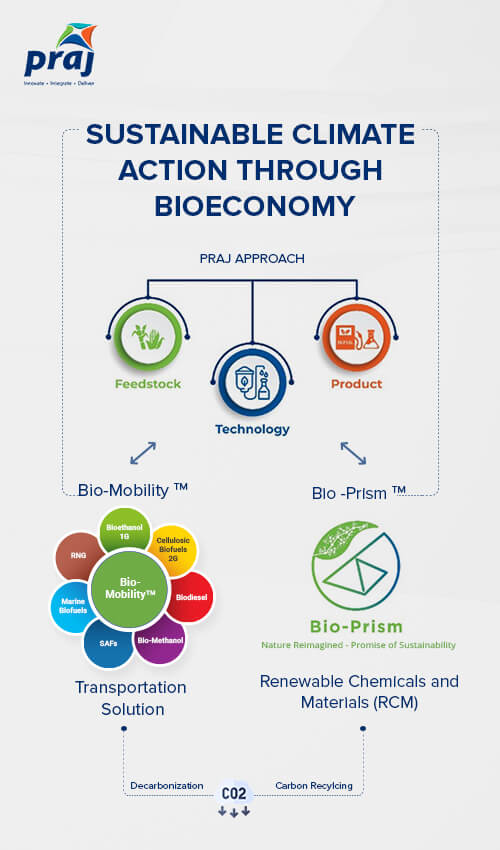

Praj Industries – India’s leading Ethanol plant manufacturers and providers of 2nd gen bio-based solutions, have been developing several state-of-art technologies to convert agricultural waste into valuable products in the form of biofuels and biochemicals. It is already the major technology provider of 2G ethanol for Indian oil companies like IOC, BPCL, HPCL and MRPL. Praj’s 2nd Generation “Bio” Ethanol technology is one that efficiently converts agricultural waste into fuel-grade ethanol. Besides ethanol, Agri waste can also be used as a raw material or feedstock to produce not only ethanol but also compressed bio-gas (CBG). As such, the growth of Ethanol Industry can prove beneficial for the farmer as well as the environment by acting as a solution to the age-old problem of disposal of Agri residue, thus solving the ‘burning’ issue to a great extent.

The Socio-Economical Impact of 2G Ethanol Production

- Second generation ethanol production technology will support 10% blending of ethanol with petrol which would result in a reduction of India’s oil import bill.

- It will reduce smog formation in future and ensure clean air for our citizens.

- Farmers will benefit from converting their agri-waste into feedstock for Industrial production of ethanol

- Increased layers in the waste management process will give rise to multiple opportunities in rural areas

- Most importantly, using 2nd generation ethanol-blended petrol will reduce GHG emission and eventually will bring down smog levels.

Challenges in Mass Commercialization of 2G

We require a robust ecosystem for a smooth functioning supply chain management of feedstock. There are still hurdles at various levels of statutory clearances and permissions such as environmental and land acquisition, which make setting up a bio-ethanol plant, a time-consuming process. Funding is again a challenge. There is still a need for mechanization of farming in India to facilitate quick and easy collection of the leftover straw after harvesting grain.

Ways to Overcome Challenges

Farmers need to be educated about wrapping straw in bales or man-made bundles for biofuel production. Using modern farm equipment, these straws can not only be extracted from the harvest but also be shaped into round or square bales to facilitate storage and transport. Financial assistance needs to be made available to co-operative societies of farmers, farmer producer organizations, registered farmer societies, rural entrepreneurs, women farmers and self-help groups. The State Govt needs to fix the minimum support price (MSP) of the straw and assure farmers of a long-term buy-back agreement for straw collected.