The Future of Bio-Based Solutions and EPC Requirements in India

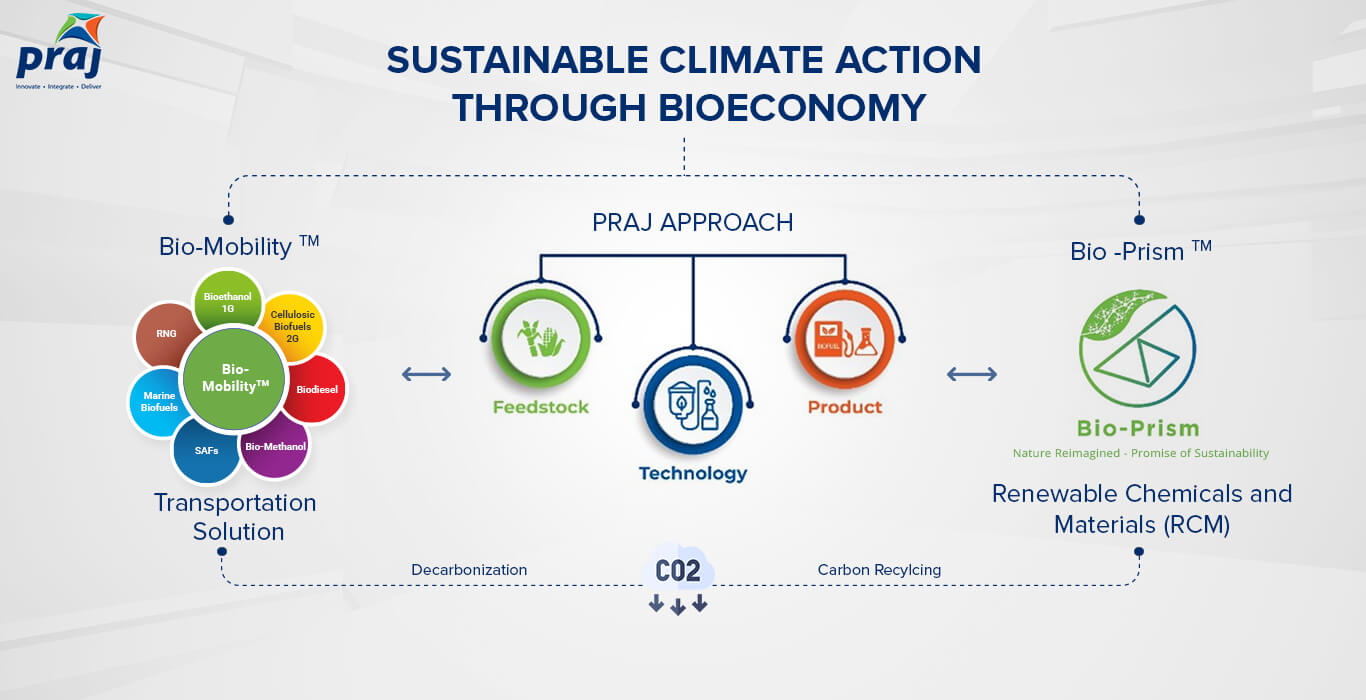

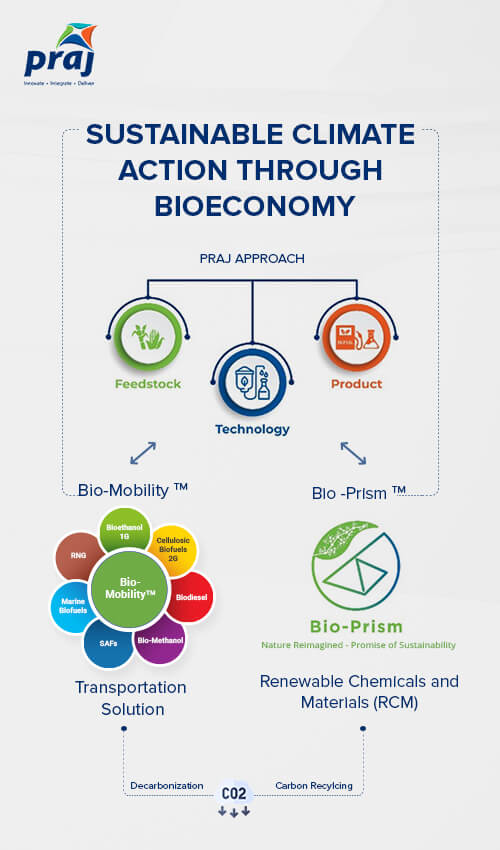

A massive increase in energy consumption throughout the world has led to a rise in demand for fuels and energy sources. Conventional energy sources such as fossil fuels are limited and on the verge of getting exhausted. Renewable fuels and technologies, hence, are sustainable solutions. More sustainable fuels that reduce emissions and social impacts such as compressed natural gas, biodiesel, renewable diesel, and electricity are required to meet today’s energy needs of India.

The global market trends are positively shifting towards cleaner fuels. This is evident especially in the international markets where they are now making modifications for larger integration of biofuels produced using ethanol from molasses. There has been a surge in the demand for 1G ethanol in international markets such as Latin America, South-East Asia and parts of Europe. Crude oil prices are soaring owing to an expected trade deal between the US and China along with growing geopolitical tensions between the US and Iran. The price increase has been around 18% for the October-December quarter. Since India is heavily dependent on imported oil, any flare-up in prices can have a serious impact on our economy. Praj – one of the leading pioneers of Ethanol plant manufacturers in India, has been an active participant and contributor in meeting the international & national demands of clean fuel in the chemical and ONGC sector and executing activities related to Engineering, Procurement, and Construction.

A Window for Several Greenfield and Brownfield Projects

These adversities have turned into opportunities for Major Oil Companies such as Exxon Mobil and Shell, as they increase their investment in oil exploration and refineries in newer oil fields, thereby creating new opportunities in greenfield projects. Old refineries, using legacy systems, are looking to expand their facilities by allowing brownfield projects seeking renovation and up-gradation of existing facilities. This also provides a great opportunity for process equipment industries to implement advanced technologies in terms of remote monitoring for performance, data analytics for optimizing product mix and quality. There is also a growing preference for skid systems and complex materials. Praj’s global certification makes it eligible for participating in various company biddings requiring bioethanol production on a global scale.

Chemical Industry and Bio-Technology

The Indian chemical industry has seen a gradual improvement in the past few years. Currently, China and India drive the growth of the chemical industry because of the availability of raw materials at a competitive price. The strong government support for research & development and an evolved ecosystem that fully supports the industry and innovation are the main contributors to growth. Other industries poised for growth are Agro Chemicals, Specialty Chemicals, Colorant Chemicals, and Renewable chemicals.

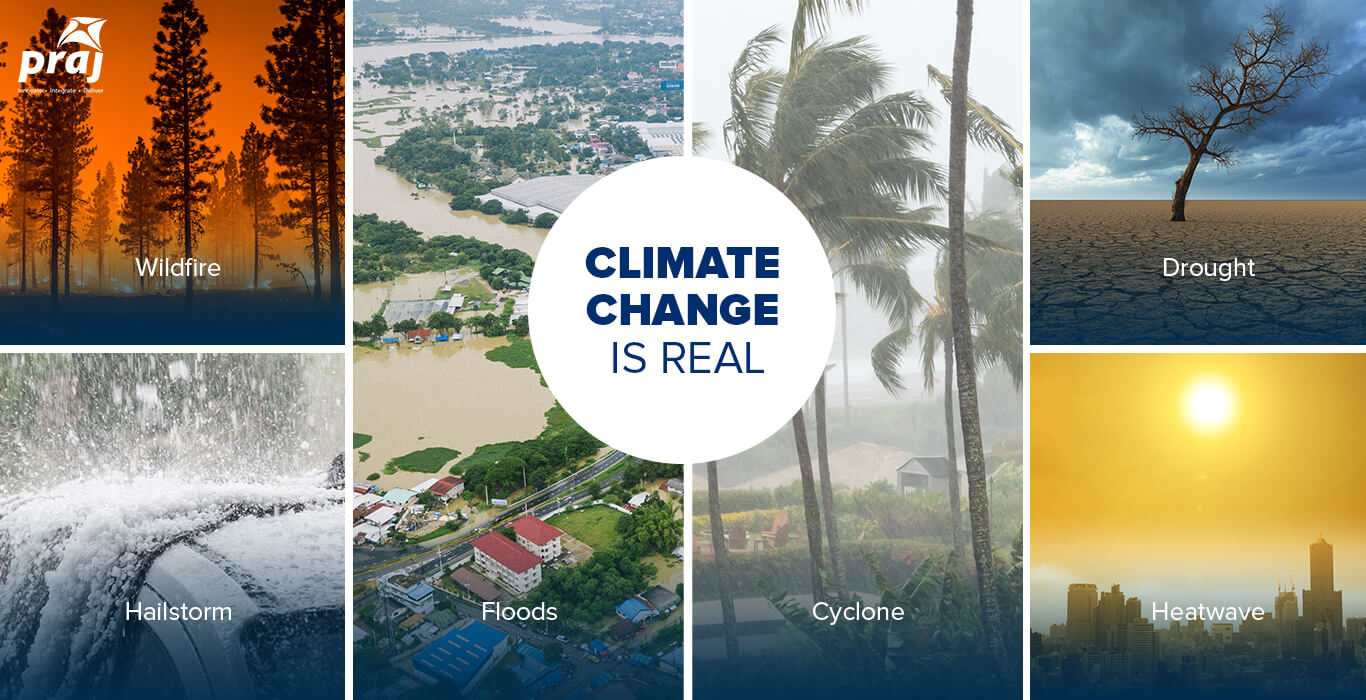

Working towards Sustainable Decarbonization

At a time when carbon emissions are attracting global attention, it has become necessary to reduce carbon footprints. This can be made possible only with the use of renewable fuels, including ethanol in petrol, use of CBG instead of CNG, use of alternative energy sources like solar panels, electric vehicles, etc. Additionally, the use of renewable chemicals instead of traditional chemicals made from fossil fuel should be implemented.

The role of 2G Ethanol in reducing Fossil Fuel dependency

2G biofuels make it possible to blend up to 20 percent without changes in the engine. This means, saving 7000 million liters worth of fossil fuel by replacing them with cellulosic ethanol. This would also result in a saving of around $4920 to $5075 million dollars. Compare this to the existing capacity of 2G which has a blending rate of 5 to 7 percent and limited availability of feedstock. Praj is actively working towards expanding the manufacturing of its second generation ethanol production plants, one for Bharat Petroleum Corporation Limited (BPCL) plant at Bargarh, Orissa and second for Indian Oil Corporation Limited (IOCL) at Panipat.